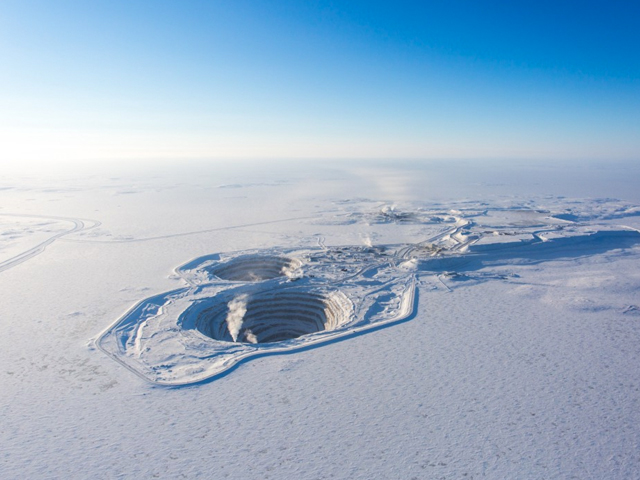

Northwest Territories, Canada

Scope of work: installation of jet grouting 1.5 metre columns for cut off, up to approximately 42 m depth.

Description

The A-418 Dike has been constructed to ultimately allow for the development of the second open-pit diamond mine in Diavik. The dike has been made water tight by the installation of a cutoff composed by plastic concrete cutoff wall, jet grouting and pressure grouting. In particular, the jet grouted cutoff was installed to seal the base of the plastic concrete cutoff wall to the pressure grouted rock. The original project schedule foresaw the start of the jet grouting production between May 2006 and September 2006. Due to Owner requirements for an earlier dewatering of the A-418 pit, the schedule was accelerated and divided in two phases:

Phase 1

Winter work Phase 1 started in February 2006 for the installation of the jet grouting in the shallowest sections. During this phase, TREVI personnel and equipment were working under a 10 metre high dome, protected against temperature as low as -50 °C, with winds blowing at 100 km per hour.

Phase 2

Summer work Phase 2 started in the month of May 2006, working in the open. The columns were installed from the top of the dike, and penetrated approximately 1.5 meter into the bedrock, which is pegmatite granite. A down-the-hole hammer, installed just below the jetting monitor, was adopted for drilling. The jetting rods were 127 mm diameter, suitable for a triple fluid jetting. Every single column was checked for verticality before its jetting phase started.

| Owner | Diavik Diamond Mines, Inc. - DDMI |

| Engineer | N.K.S.L. |

| General Contractor | Lac De Gras (Kiewit) |

The Jet Grouting contract value was $14 million Canadian Dollars and the work consisted in the installation of a single line cutoff wall for a total of 1,169 columns with depth exceeding 135 ft. Prior to carrying out any work, a series of tests were conducted to determine the characteristics and parameters to be used for jetting.

The first phase of the work was performed during the winter months with temperatures reaching the -50 degrees Celsius (-58 Fahrenheit). Work was conducted inside heated domes for both the drilling and mixing operations.

The second phase of the work was carried out during the summer months, after the installation of the plastic concrete diaphragm wall and grout curtain by others. The work was completed on schedule in approximately 7 months.

The equipment used, manufactured by Soilmec, was customized for use in the demanding conditions imposed by the site.